charpy impact testing report|charpy impact test calculation table : service Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

28 de jan. de 2023 · 新たな世界の旅路より! Free Download with Direct Links, Google Drive, MEGA, Torrent. 冒険者を生業とする主人公は、いつも通りギルドに依頼を受けていた .

{plog:ftitle_list}

Resultado da 22 de jan. de 2020 · ¿Ya tienes tu Tag TeleVía? Perfecto. Ahora conoce tus opciones para mantenerlo siempre con saldo. 🚘

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being.

The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMAlthough two standardized tests, the Charpy and Izod, were designed and used extensively to measure the impact energy, Charpy v-notched impact tests are more common in practice. .

The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . 2. ABSTRACT In the material testing laboratory, a Charpy impact test was performed on three different types (hot,cold,and steel alloy)of steels testing each variety at four different temperatures (32°C(RT), 100°C,0°C and .

the impact test, the energy absorbed in foot-pound, ft and the energy converted to the International System of Units. Table 4. Impact Energy Absorbed for AISI 1045 Low Temperature Water Bath. Specime n Temperature, T, oC Measured .

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized.charpy impact testing lab report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides instructions for conducting a Charpy impact test to investigate how the energy absorbed during deformation and fracture of metals varies with temperature. Students will perform Charpy tests on copper alloy and aluminum alloy .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . while the percentage crystallinity and lateral expansion are optional on the test report. It should be emphasised that Charpy tests are .Download Charpy impact test report and more Advanced Machining Processes Lab Reports in PDF only on Docsity! Experiment No. 2 Charpy Impact Test Shiva Yadav Aerospace Engineering, 3rd Sem (Dated: August 10, 2022) This report is a summary of the experiment to determine the Toughness of materials known as the Charpy Impact Testing .

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch .

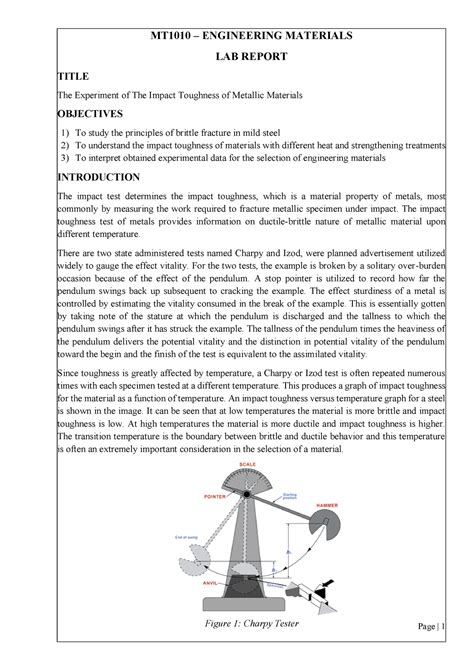

The overall purpose of this research is to explore the usage of an impact testing machine, specifically the Charpy Impact Test device, to better understand the principles behind impact testing in order to further develop engineering skills in materials selection. . ENME 2711 SEC 001 Charpy Impact Test Laboratory Report Experiment I lab report .specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.steel plate would pass a Charpy impact test has been developed. This was done to prevent testing material that would not pass the required Charpy test, without having to sample the plate for grain size. Avoiding testing plates that would not pass would preclude loss of material and time, resulting in savings for the com- pany.

IMPACT TESTING Objective To conduct Charpy V-notch impact test and determine the ductile-brittle transition temperature of steels. Equipment . CHECKLIST FOR FATIGUE TEST REPORT 1. Table of Contents with page numbers. 2. Report organized into appropriate sections. Abstract, Introduction, etc. 3. Introduction section:

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

Background – Impact Testing Toughness is a measure of the amount of energy a material can absorb before fracturing. It becomes of engineering importance when the ability of a material to withstand an impact load without fracturing is considered. Impact test conditions were chosen to represent those most severe relative to the potential Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

ME220 -- Mechanics of Materials Laboratory Test Title: Charpy Impact Test Date of Test: 7/02/2018 Date Report Submitted: 7/16/2018 Name: Cameron Quy Section: Group 1 1. Summary Purpose: The purpose of this .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).Charpy Impact Test Lab Report; Charpy Impact Test Diagram; Introduction: the charpy impact test is one of the impact-testing that is used to determine the resistance towards a sudden load or impact. Impacted specimens with small fracture or with a very little plastic deformation is said to be in a brittle manner whereas fracture of metal after .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Charpy impact is a standardized high strain rate test to measure energy absorption during fracture. The absorbed energy provides an indirect measure of fracture toughness. Despite its relative ease of use, complex energy loss mechanisms are involved, making it impossible to verify test machine performance directly. Periodic testing of impact .Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

impact test report pdf

ABSTRACT The following experimental report will discuss the importance of the Charpy Impact test and how it is used to understand the energy absorption of different materials (Steel, Aluminium and Brass). Furthermore, the experiment will test how different temperatures, grain boundary orientations and the lattice structure can affect the fracture pattern of the material.

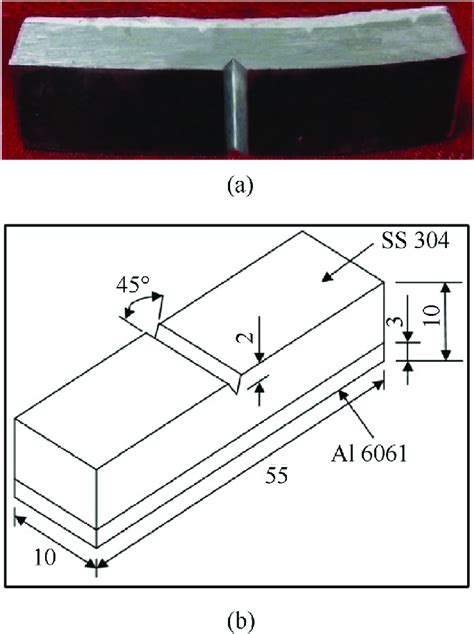

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :What is Charpy value a measure of? Ans: The Charpy impact value is calculated by dividing the fracture energy by the cross-section area of the specimen. So, area of cold rolled steel used at the time of experiment is 0 ft². For workpiece having room temperature, charpy impact value will be .The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .

kruskal wallis test in r package

kruskal test from r stats package

web1.215 garotas de programa em Ribeirão Preto agora diponíveis, 35 TD com escorts contados por clientes reais e 26 vídeos de acompanhantes. Eliminados 191.686 .

charpy impact testing report|charpy impact test calculation table